The smart Trick of In Fill Panels That Nobody is Discussing

Table of ContentsSome Ideas on In Fill Panels You Should KnowIn Fill Panels Things To Know Before You Get ThisThe Buzz on In Fill PanelsThe smart Trick of In Fill Panels That Nobody is Talking About

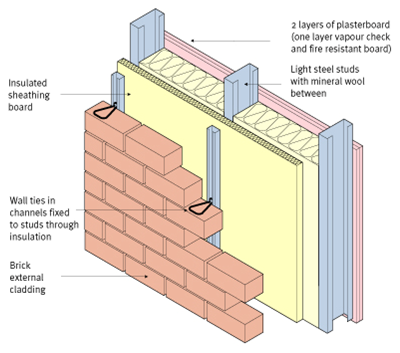

@&&h3@ [leading] Infill wall surfaces supporting external fallen leave of brickwork @&&/h3@ Brickwork might be ground supported or sustained at each flooring. In both situations, the infill wall provides just side support via wall surface ties attached in upright 'runners' that are screw fixed via the insulation to the C areas. For buildings greater than 3 or in some cases 4 storeys high, the brickwork is sustained by proprietary stainless-steel angles that are connected to the edge light beams as shown listed below. A common cross-section via an exterior wall surface using stainless-steel angle assistances is likewise shown. The usage of brickwork at first stage degree as well as numerous types of light-weight cladding above need to enable a' step-out' and flashings at the brickwork, which is thicker than the cladding over. @&&h3@ [top] Infill wall surface sustaining light weight cladding @&&/h3@ Various types of light-weight cladding may be made use of with light steel infill walls, as complies with: Insulated make that is adhered to a sheathing board and also often a small tooth cavity is additionally offered Rain-screen cladding, that might remain in the form of boards, metal sheets or floor tiles connected to straight rails Metal systems, such as composite panels (also referred to as sandwich panels), to which horizontal rails may be affixed to provide support for terracotta ceramic tiles, and so on. Some instances of light-weight cladding affixed to infill walls are received the figures on the right.

In the majority of uses rainscreen cladding, a sheathing board is affixed to the outside face of. in fill panels.

The Basic Principles Of In Fill Panels

the infill walls to attend to weather resistance, both in the building and construction and also in-service problems. It might be in the form of cement particle boards, calcium silicate board or, for insulated provide applications, moisture resistant plasterboard. @&&h2@ [leading] Efficiency needs for dividing walls @ & &/ h2 @. Separating walls have various efficiency needs to exterior wall surfaces as well as are explained as complies with. @ & & h3 @ [top] Acoustic efficiency @&&/h3@ @&&h3@ [leading] Fire resistance of separating walls @ & &/ h3 @. @&&h3@ [leading] Tons resistance of internal walls @&&/h3@ @&&h2@ [leading] Recommendations @&&/h2@ @&&h2@ [top] Further find more info analysis @&&/h2@ @&&h2@ [leading] Resources @&&/h2@ @&&h2@ [top] See additionally @&&/h2@ @&&h2@ [top] Exterior web links @&&/h2@ @&&h2@ Bound wire infills. Limitless presence, security, and aesthetic appeals. @&&/h2@ @&&h3@ Functions @&&/h3@ @&&h2@ Infill Panels for Railings @&&/h2@ @&&h3@ Barrier Infill Panels @&&/h3@ Security is the name of the video game when it involves infill panels for railings. You can really feel positive and have miraculous rely on the high-grade stainless-steel utilized in our cables. Our infills are made with alloy 316 and can be fitted to your requirements. The frameworks are custom made as well as can be sized relying on your needed dimensions. We use you both a round over-the-frame variation, or a much more modern appearance with a version that is protected in-frame. The clamps for these components are also custom-made , and secure straight to your barrier system, or by utilizing straightforward tabs. These advantages incorporated with the ease of setup make these infill panels a very easy option for listed below your railings. Regardless of what size you require, you can find a variation below that will certainly fit your specifications.

What is absolutely the very best component regarding this product is that as soon as it's mounted, it's maintenance-free.

The stainless-steel will push moved here back the components as well as stay looking bright and also tidy all year long. If you can not discover what you.

Some Known Details About In Fill Panels

manner. @&&h2@ Exactly how To Modification The Colour Of The Ends Of Your Systems @&&/h2@

If you want to alter the colour at the end of your systems you have got 2 alternatives You can apply a panel which is a fantastic option if you intend to include some added thickness sideways of the system. However, if adding density sideways of a cupboard is going to be an issue for, example on the sides of the unit over a hob where the extractor is, you might not have the room to fit the extra density of a panel, then self-adhesive vinyl maybe an excellent option for you.

Some Ideas on In Fill Panels You Need To Know

Panels are made from the same product as our doors so they are a specific colour match. The rear of the panel is made from the same material as the rear of our doors to ensure that's the same colour too. Our panels are ended up on all edges (in fill panels).